Choosing the Right Polishing Sander for Your Project: Factors to Consider

Choosing the right polishing sander for your project is crucial to achieving the desired results. Several factors should be considered when making your decision. Here are some key factors to keep in mind:

Type of Project: Consider the specific project you're working on. Are you polishing wood, metal, or other materials? Different sanders are designed for different purposes.

Speed and Power: Evaluate the speed and power requirements for your project. Higher speeds and more power can be beneficial for tackling tough materials or achieving a faster sanding process. However, for delicate surfaces, you may need a sander with variable speed settings to avoid causing damage.

Size and Weight: Consider the size and weight of the sander. If you have a large project or need to work in tight spaces, a compact and lightweight sander might be more suitable. On the other hand, larger sanders may offer more stability and better control for heavy-duty tasks.

Sanding Mechanism: Different sanding mechanisms produce different results. Orbital sanders, including random orbital and orbital sheet sanders, create a swirling motion that helps prevent swirl marks. Rotary sanders, such as rotary disc sanders, move in a circular pattern and are more aggressive for material removal. Choose the mechanism that suits your project requirements.

Dust Collection: Consider the dust collection system of the sander. Sanding generates a significant amount of dust, which can be hazardous to your health and affect the quality of your work. Look for sanders with effective dust collection features such as integrated dust bags or vacuum attachments to keep your work area clean and minimize airborne particles.

Ergonomics and Comfort: Since sanding can be a time-consuming task, it's important to choose a sander that offers comfort and ergonomic features. Look for sanders with well-designed handles, vibration reduction technology, and adjustable grips to minimize fatigue during extended use.

Budget: Lastly, consider your budget. Sanders come in various price ranges, and while it's important to invest in a quality tool, you should also consider the cost-effectiveness for your specific project. Determine your budget and find a sander that offers a good balance between features, quality, and affordability.

By considering these factors, you'll be able to choose the right polishing sander that matches your project requirements, enhances your efficiency, and delivers high-quality results.

From Wood to Metal: Polishing Sanders for Various Materials

When it comes to polishing different materials, such as wood and metal, specific types of sanders are more suitable for each task. Here are some recommendations for polishing sanders based on the materials you're working with:

Wood:

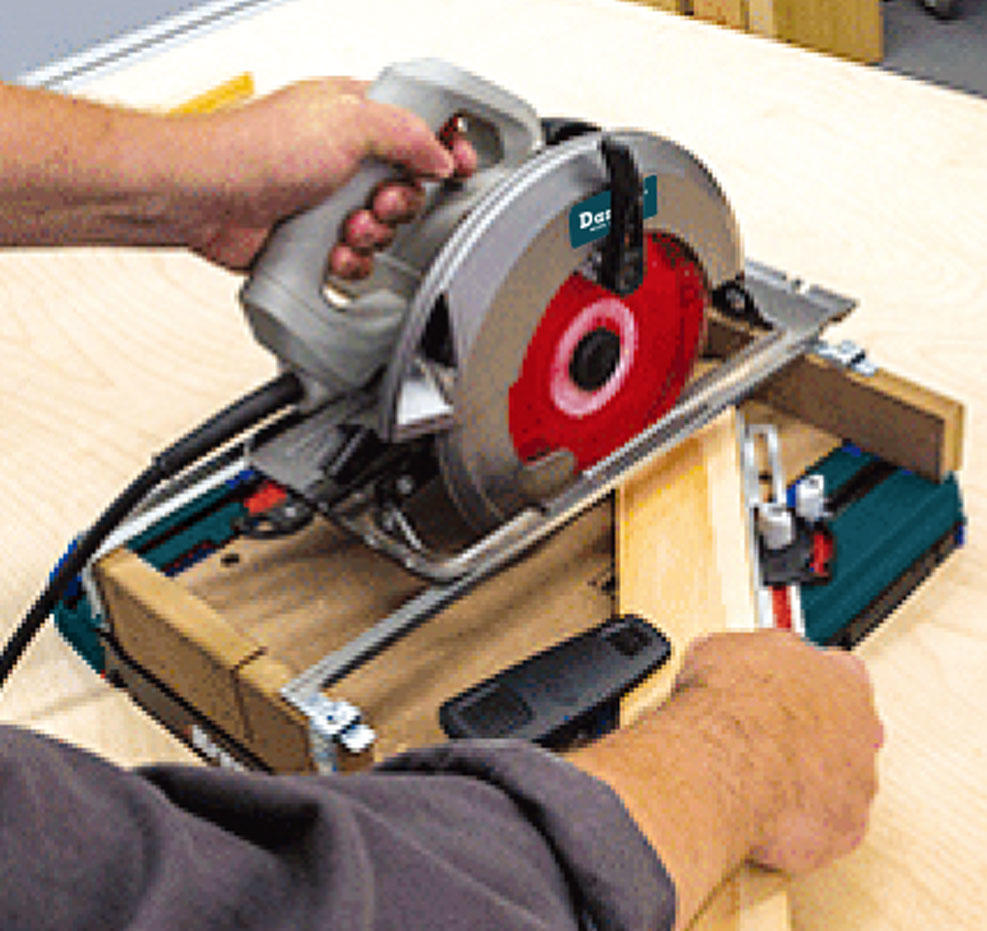

Random Orbital Sander: This type of sander is versatile and commonly used for sanding and polishing wood. It provides a swirl-free finish and is effective for removing scratches and blemishes.

Finishing Sander: Also known as a palm sander, this sander is suitable for fine finishing work on wood surfaces. It has a square or rectangular sanding pad that moves in small orbits.

Detail Sander: This sander is designed for reaching into tight corners and intricate details on wood surfaces. It usually has a triangular sanding pad.

Metal:

Belt Sander: Metal often requires more aggressive sanding to remove rust, paint, or welds. A belt sander with a coarse-grit belt is effective for heavy material removal on metal surfaces.

Disc Sander: A rotary disc sander with a sanding disc specifically designed for metal can be used to remove burrs, smooth edges, or shape metal pieces.

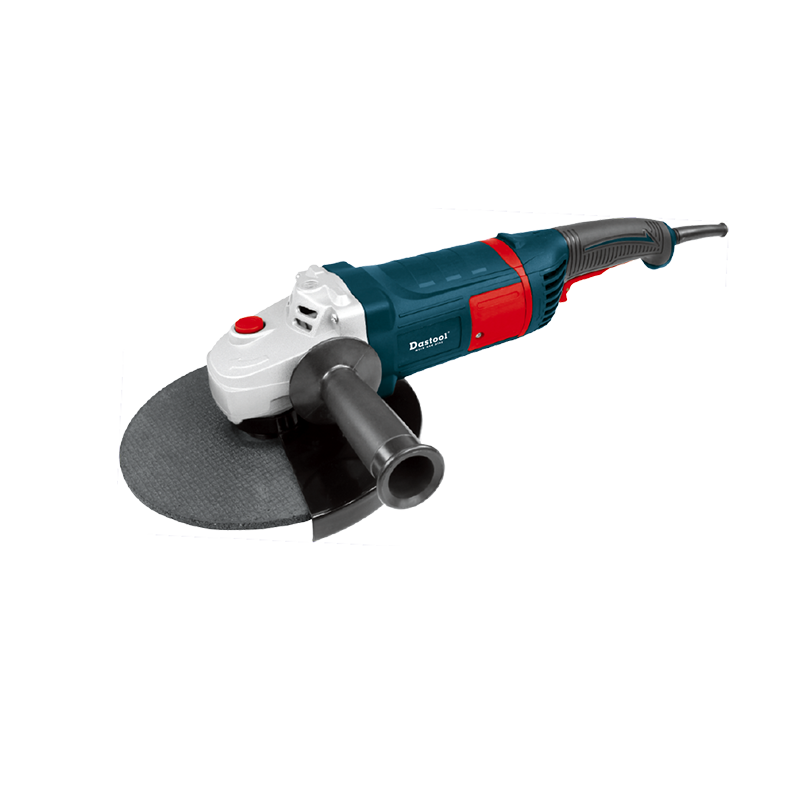

Angle Grinder with Flap Discs: For heavy-duty metal polishing and grinding tasks, an angle grinder equipped with flap discs can be effective. Flap discs are abrasive discs with overlapping flaps that provide controlled material removal and produce a smooth finish.

Multi-purpose:

Random Orbital Sander: As mentioned earlier, a random orbital sander is versatile and can be used for both wood and metal projects. Ensure you use appropriate sandpaper with different grits based on the material you're working on.